China is seeking to strengthen its position as a dominant country in the automotive industry by developing cutting-edge battery technology for use in electric vehicles (EVs).

The country is already a leader in EV production and GlobalData's Global light vehicle hybrids and EVs According to the database, EV and hybrid sales in 2023 will be 11.42 million units, almost 3.5 times the next closest country, the United States, which has 3.35 million units.

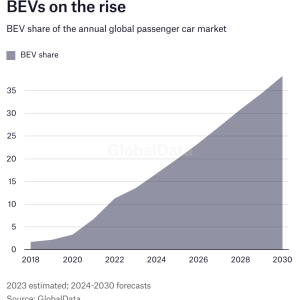

However, the EV industry is still in its relative infancy, with sales expected to grow rapidly at a compound rate of 16.1% from 2023 to 2028, reaching 53.9 million units, according to GlobalData research. 2024 Automotive Forecast Report.

During this period, battery electric vehicle (BEV) production is expected to surpass hybrid vehicle (HEV) production, and China is expected to increase its strategic efforts by national governments to promote cooperation.

China's EV battery technology

Regarding the outlook for China, Tom Bloor, managing director of EV charging company Evec, said: just auto: “China is leading the way in EV sales. Currently. It accounts for 60% of global sales. The company expects new EV sales to increase by 82% in 2022 and further increase in the coming year. There is.

“Battery technology is driving the global growth of EVs. Manufacturers who can produce batteries that offer more range and performance have a large portion of the market. One of the most important considerations for those choosing: If BYD could offer 600 miles of range and Tesla only has 400 miles, most people would buy BYD and have less range. If the fuel tank is longer than the fuel tank, we would encourage petrol/diesel drivers to switch.”

Access the most comprehensive company profiles on the market with GlobalData. Save research time. Increase competitiveness.

Company Profile – Free Sample

You will receive a download email shortly

We are confident in the unique quality of our company profile. However, we want you to make the decision that is most beneficial for your business, so we are offering free samples that you can download by submitting the form below.

by global data

In fact, BYD is one of a number of major Chinese EV manufacturers that have joined a government-led partnership to accelerate the development of solid-state batteries that are expected to revolutionize the EV industry.

Solid-state batteries (SSBs) work much like traditional lithium-ion batteries, but they use a solid electrolyte rather than a liquid electrolyte, and the electrolyte manufactured for EVs is most commonly sodium ion. . The first SSB-equipped vehicles are expected to hit the road in 2025, so it's still a long way off, but EV batteries are lighter, can hold more energy, and can be charged more quickly. It has been widely hailed as the next leap forward in technology. , safer and longer lasting.

The China All-Solid Battery Collaborative Innovation Platform (CASIP) Alliance aims to lead the world in all-solid-state battery technology, and six of the world's top 10 automotive battery manufacturers are reportedly members. ing.

Regarding the CASIP initiative, Chen Qingtai, representative of the China EV100, which examines industrial policy regarding EVs, said: Nikkei Shimbun “China has led the world in new energy vehicles with its advanced battery technology,” he said, arguing that new solid-state battery technology should be prioritized to build on that position.

Mr. Chen’s claims have weight – GlobalData car prediction The report states, “In 2023, China will account for 73% of the world's battery cell production for light vehicle BEVs.” The country is expected to remain the world's top supplier of BEV battery cells throughout the decade in terms of production, although this number is expected to decline as competition from other countries increases.

All-solid-state EV battery technology

Oliver Pechenik, a powertrain analyst at GlobalData, elaborated on this. just auto: “China is taking the lead in producing budget-friendly cobalt-free battery solutions, such as lithium iron phosphate (LFP), which currently has a proven low cost that meets many of the requirements for automobiles. It is a cost chemical, with low cost, high life cycle capability, and good safety, and is mainly produced in China.

“While some LFP-equipped models are sold at very close price points to their internal combustion engine (ICE) equivalent segments, the fact that ICE vehicles are becoming more expensive, especially due to emissions regulations, overlap, and I think sodium ions are the key to making BEVs cheaper than ICEs. The energy density is very low, but when combined with the packing density of LFP cells, it seems to be a viable solution. Masu.

“Currently targeted only at superminis, but as soon as sodium ion technology advances (although it is still in its early stages) it will become a mainstream technology for non-long range/high performance EVs (aka low cost EVs). I believe it's possible.'' As far as I know, only two factories are planned outside of China, so after all China is “ahead'' in this technology as well. ”

In particular, Pechenik points out that Toyota has delayed its much-touted SSB plans for years, and is not convinced that SSB has yet reached the stage where it can be mass-produced without losing its associated benefits. Not yet.

“There are too many tolerance and uniformity concerns for mass production of ceramic-based SSBs, and polymer-based cells appear to have lower power capacity and temperature performance issues. I have no doubt it will be on board, but I still don't think it will be as groundbreaking as everyone is hoping.

“However, I am confident that semi-solid batteries will become more widespread. Make it possible.

“And again, all known and planned production is coming from China. We expect China to maintain the lion's share of battery production, which will leverage BEV production.”